GALA INDUSTRIES, INC [Underwater Pelletizing System]

Underwater Pelletizing System manufactured by Gala Industries, Inc (MAAG Group)

GALA UNDERWATER PELLETIZING SYSTEM~

[What is Underwater Pelletizing]

A process of pelletizing by cutting and cooling heated and melted resin in water.

[Overview]

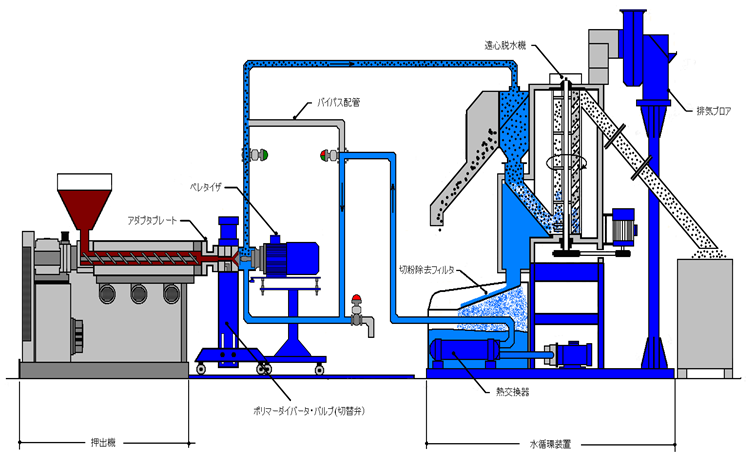

The melted polymer is transported downstream by an extruder or gear pump and extruded from the die plate (mold) into the cutting chamber. The inside of the cutting chamber is filled with circulating water, and the polymer extruded into the chamber is cut by the cutter rotating at high speed and instantly cooled by the circulating water to be pelletized. The pellets are transported with the circulating water to the centrifugal dryer, where they are separated into water and pellets inside the dryer, and the dried pellets are discharged from the dryer outlet. The water separated in the dryer returns to the tank through a filter, and is sent to the cutting chamber through a heat exchanger.

[Characteristics of Gala Underwater Pelltizer System]

■ Easy operation that anybody can do

(1) Fill the die plate hole with resin.

(2) Clean the die surface.

(3) Connect the cutting chamber and pelletizer (cutter).

(4) Push the auto start button.

With these four steps, you can produce high quality pellets constantly.

■ Stable and continuous production is possible.

No worries about strand breakage, etc., and excellent operability allows one person to manage multiple lines.

■ Space saving

The pelletizer does not require a long water tank, and there are no restrictions on the position of the pelletizer in relation to the circulation system. Compared to strand cutters, three to four lines can be laid out in the same space as two lines.

■ No need for meticulous centering work

The cutter hub, which automatically tracks and aligns with the die surface, eliminates the need for time-consuming, meticulous surface preparation and centering work.

■ Clog-resistant die plate

The die plate structure, which has a reputation for being clog-resistant, and its temperature control technology have greatly expanded the range of applicable material grades.

[Support System] Through trial tests in our laboratory in Japan and discussions on mechanical and electrical specifications, we offer the optimal solution for the stable production of materials with various characteristics according to the equipment operation method and installation site conditions. In addition, we will dispatch technical service personnel after the equipment delivery, and sell maintenance parts (some of which are held in stock in Japan), making full use of our network to provide the best possible support for quick troubleshooting.

[Applications, Experience]

■ Applicable Materials and Applications

・ General materials such as olefins

・ Thermoplastic elastomers

・ Biodegradable resins

・ Hot melt

・ General-purpose engineering plastics, super engineering plastics such as LCP, etc.

・ Micro pellets (pellets with a diameter of 1.0 mm or less)

■ Sales History

Gala has delivered more than 6,000 lines of underwater pelletizing systems around the world.

In Japan, we started importing and selling these systems in 1991, and have delivered more than 200 lines.

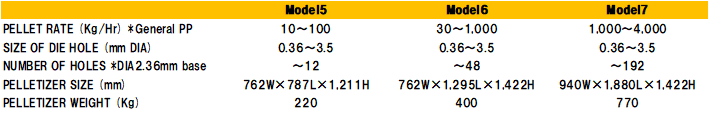

[Product Specifications]

[Contact/ Product information download]

- If you have any questions, please feel free to contact us using the email form.

- Please fill out the required fields and download the detailed product informaiton (PDF)

Please feel free to contact us with any questions

from the e-mail form.