ALIGNED VISION

Laser Projector by Aligned Vision

Aligned Vision's laser projectors are widely used in the aerospace industry, and also for wind power generation blades, F1 racing cars and shipbuilding. For manual layup on a jig for composite manufacturing, the shape data of each ply in a CATIA model is converted into laser projection data by separate custom software, and the necessary ply data is projected sequentially based on the data, therefore reducing the number of template changes and labor costs. This laser projector has a multitasking function that allows a single control PC to control up to 12 projectors simultaneously, and also allows a single projector to project onto multiple objects at the same time.

Laser projectors are available in the following three models depending on the application.

-

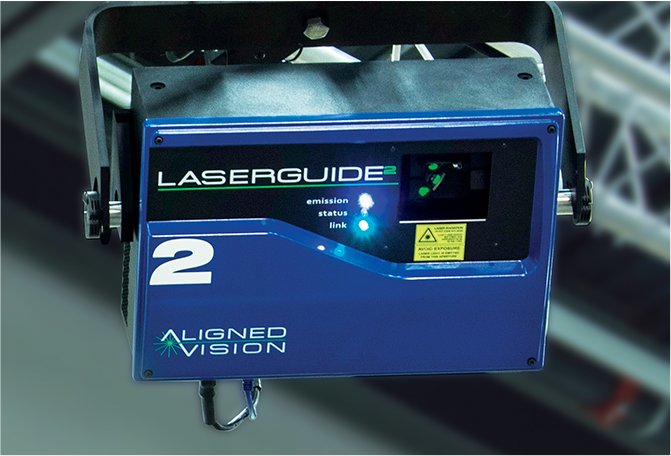

1) LASERGUIDE2

Standard laser projector

・ High laser position accuracy

・ 3D laser projection

・ Reliable laser safety standard class 2 (CDRH / IEC)

・ Laser unit that is hard to break and has excellent durability

・ Automatic laser focus adjustment function (optional)

-

2) MicroLASERGUIDE

Smaller laser projection unit makes it ideal for work in places where space is limited.

・ Half size of LASER GUIDE 2

・ Space saving and improved portability

-

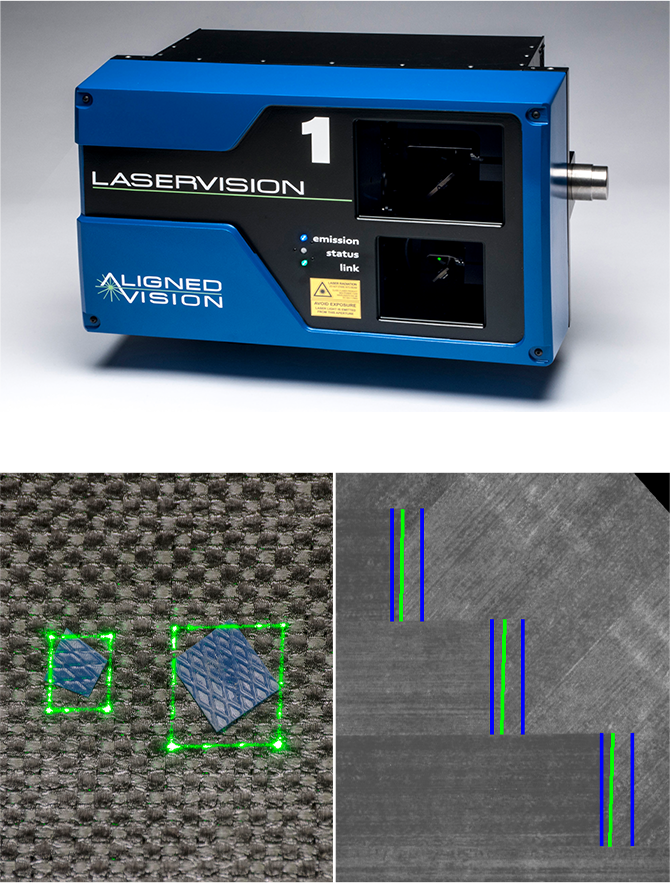

3) LASERVISION

In addition to the same laser projection function as the LASERGUIDE2, the inspection can be automated by image analysis using a built-in camera.

・ Foreign material detection function

・ Composite fiber direction detection function

・ Edge detection function

Optional Products

Can be used in conjunction with laser projectors to further improve work efficiency.

-

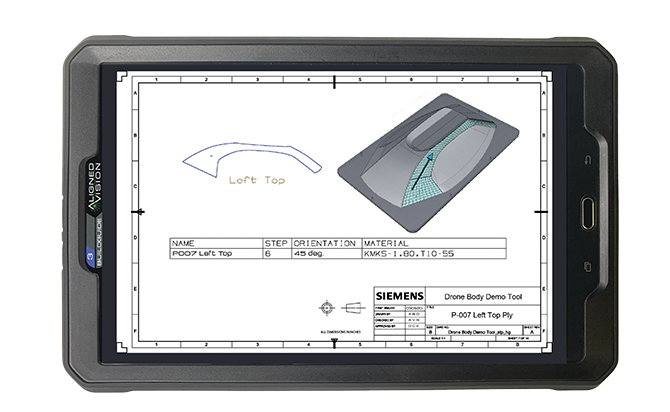

1) Remote Controller

Remote control of laser projectors is possible with a smartphone or tablet device.

・ No need to go back and forth from the work area to the PC for operation.

・ The image display enables visual confirmation of work procedures and work content while at the work site.

-

2) AutoAim Unit

By attaching it to a laser projector, an automatic pivoting function can be added to expand the possible projection range.

・ The swivel angle can be set on the laser operation software.

・ Especially compatible with MicroLASERGUIDE

-

3) TARGETGUIDE Unit

Automatic detection of target position by adding a laser projector

・ Target position can be automatically detected by image analysis using a camera.

・ Automates the target reading process in preparation for laser projection.

-

4) BUILDGUIDE

By adding this function to the software, it is possible to digitize the manufacturing process.

・ Display work procedures on the remote control using text and image data.

・ Automatic electronic reports can be generated to record the operator, the work performed, and the time spent on the work.

Application

-

1) KIT GUIDE

The KIT GUIDE system facilitates the management of plies after cutting by linking the cutting machine, the system and the laser projector. The operator presses the print button on the handheld printer linked to the system, and the laser projector illuminates the center of the designated ply and attaches the barcode label from the printer. This process can be done sequentially to facilitate the management of each ply.

-

2) Other System Integration

Aligned Vision's laser projectors and the LASERGUIDE software that controls them are expandable. By incorporating the control function of the laser projector into the operation program of other equipment, it is possible to incorporate the position indication and inspection assistance function by laser projection into the system. For more information about Aligned Vision's system integration experience, please refer to Aligned Vision's website.

Please feel free to contact us with any questions

from the e-mail form.